Kiln inlet and outlet systems

The inlet and outlet seals separate the kiln process from the environment. The aim is to seal against false air, with maximum process reliability and availability. The sealing systems from thyssenkrupp Polysius are independent of the kiln manufacturer and can be retrofitted without additional modifications to the kiln.

Spare parts management

In the spare and wear parts business, we focus on shortening the unscheduled downtimes of our customers‘ plants and improving plant performance.

To achieve this, our team of experts examines the individual production processes and based on their OEM expertise and new material technologies, develops suitable wear part solutions for the respective application in combination with appropriate business models.

Thanks to our long-term experience as an OEM supplier, we can provide innovative spare parts concepts to meet your quality and performance requirements: on the one hand, the engineering and manufacturing of individual spare parts in line with your requirements; on the other hand, the ongoing development and enhancement of spare parts and components to increase the availability and performance of your plant. We also offer spare and wear parts for plants that were engineered and erected by third parties.

Highlight Services

- Mobile oil circulation lubrication

- Standard initial parts: kiln tyre, supporting rollers, supporting roller bearings, bearing housings, supporting roller fastening systems

Modernisation measures

The retrofitting or replacement of the existing sealing systems is possible without further ado. The fastening system on the inlet and outlet side is independent of the kiln manufacturer and makes it possible to compensate for age-related signs of use.

On-site services

Highlight Services

- Inspections

- Repair services

- Training

Digital services

Videos

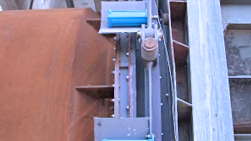

Inlet and outlet graphite seals separate the kiln process from the environment. They are designed to seal off the kiln process from leak air while ensuring maximum process reliability and availability. No additional modifications of the kiln are necessary to retrofit the polysius® graphite seals - independent of the kiln manufacturer.

Rotary kiln with graphite block seal – effective sealing, designed for easy mounting

Plant References: PHOENIX Zementwerke – New graphite block seal for increased kiln performance

Project description

The client PHOENIX decided to install our new designed kiln outlet sealing system with graphite blocks. A special challenge was the short delivery time for creating the technical drawings and manufacturing. And of course the installation for this unknown prototype during 10 days.

Results

- False air reduced

- Performance increased

- Increased secondary air use

- Clean and safety burner platform

Customer: PHOENIX Zementwerke

Location: Beckum, Germany

Plant type: Plant for cement production

Service type: Spare parts