Materials Handling

Conveying technology has a tradition of over 80 years at Polysius and has been continuously developed during this time. Our portfolio includes pneumatic conveying, mechanical conveying technology and coarse feed valve.

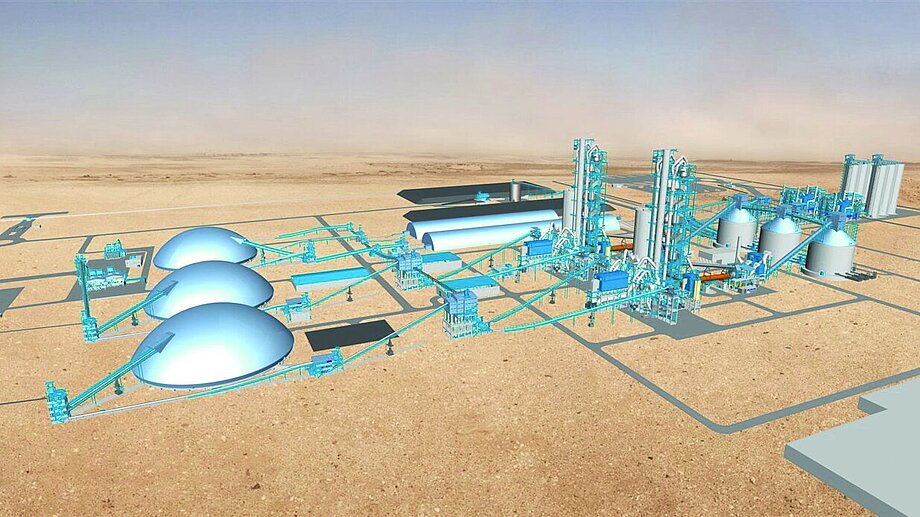

Raw Material and Blending Storing

Different materials for the raw mixture and the cement are stored in piles where stackers and reclaimers operate. The operation of these machines can be automated.

Raw Material and Blending Technology

A storage facility for bulk materials used in cement production lines typically looks like a low-tech operation. Building on its industry-leading expertise in this field, Polysius has brought high technology to bulk storage.

Silo Technology and Pneumatic Conveying

The Polysius portfolio includes all the silo types that the cement industry needs: from small steel silos to large storage silos. At Polysius, pneumatic conveying and dosing has an 80-year-long tradition and has been continuosly advanced over this period.

Mechanical Conveying

Mechanical conveying technology has become increasingly important. Polysius can offer consultancy services and service assignments in order to solve process-technology problems and respond to changes in the conveying-task requirements.

Coarse Feed Valve

Coarse feed valves serve as airlocks and as continuous feeding units for coarse-grained materials. They minimize the effect of false air in a grinding system operated under negative pressure and permit continuous further conveyance of the materials. Polysius spring-plate cell airlocks are particularly worthy of mention. They are of a robust cast design and have been in use successfully for decades, for air sealing and dosing tasks.