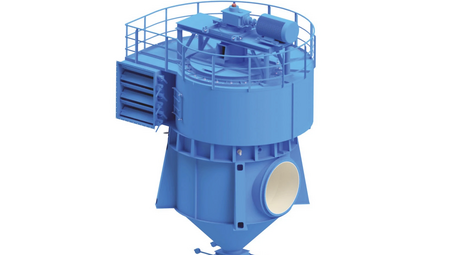

sepol® - High-efficiency Separator

The higher the demands placed on the quality of the ground material and the lower the desired energy requirement of the overall grinding system, the more important the efficiency of the separator is.

High availability, high selectivity, low specific energy consumption, simultaneous product separation, cooling and drying, as well as short amortization periods combined with relatively low capital expenditure are the defining features of the sepol® high-efficiency separator. All the requirements that define a future-proof system configuration are precisely fulfilled by the sepol® high-efficiency separator.

The separator plays a key role in grinding systems equipped with tube mills, roller mills and high-pressure grinding rolls.

Over 1,000 sepol® separators installed around the world confirm this effective functional principle.

Spare parts management

In the spare and wear parts business, we focus on shortening the unscheduled downtimes of our customers‘ plants and improving plant performance.

To achieve this, our team of experts examines the individual production processes and based on their OEM expertise and new material technologies, develops suitable wear part solutions for the respective application in combination with appropriate business models.

Thanks to our long-term experience as an OEM supplier, we can provide innovative spare parts concepts to meet your quality and performance requirements: on the one hand, the engineering and manufacturing of individual spare parts in line with your requirements; on the other hand, the ongoing development and enhancement of spare parts and components to increase the availability and performance of your plant. We also offer spare and wear parts for plants that were engineered and erected by third parties.

Highlight Services

- Bearings

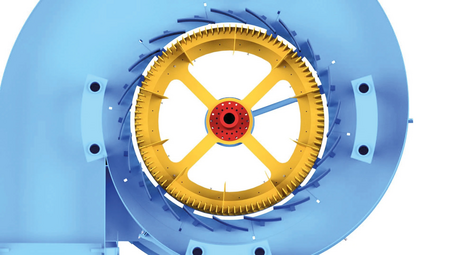

- Rotor blades

- Guide vanes

- Rotor sealing

- Rotors

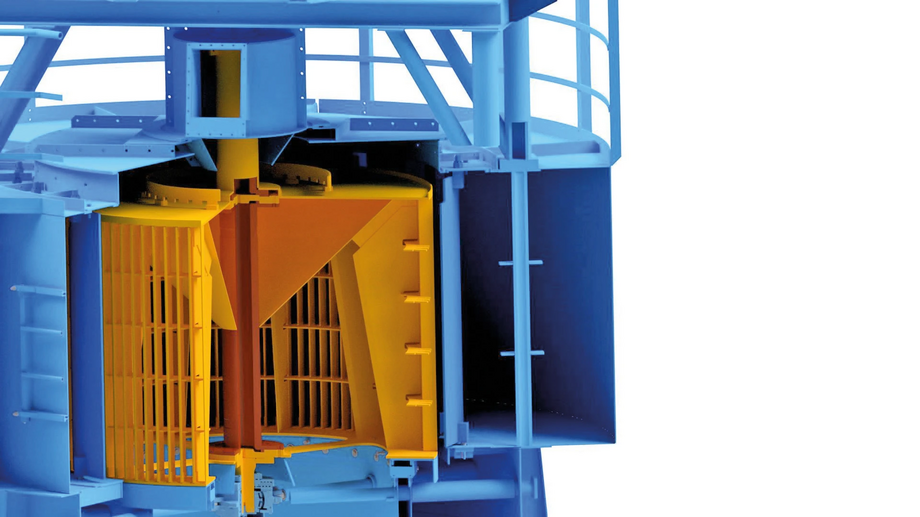

Modernisation measures

Thanks to their modular design, all sepol® sifters can be retrofitted or upgraded. By retrofitting, the wear protection concept can be individually adapted to the respective requirements in the event of operational changes (such as increased slag grinding or a change in the maintenance interval).

Highlight Services

- Swirl crusher conversion

- curved blade conversion

- rotor seal conversion

On-site services

Maximum availability of the system is crucial for economic success. To ensure this, we offer you various forms of inspection, repair and maintenance services by our trained specialists. Our offer includes numerous measures that can be carried out individually or combined according to your requirements.

Highlight Services

- Inspections

- Repair Services

- Drive Inspection

- Training

Digital services

Highlight Services

- Experience since 2012

- Various communication options

- Worldwide availability