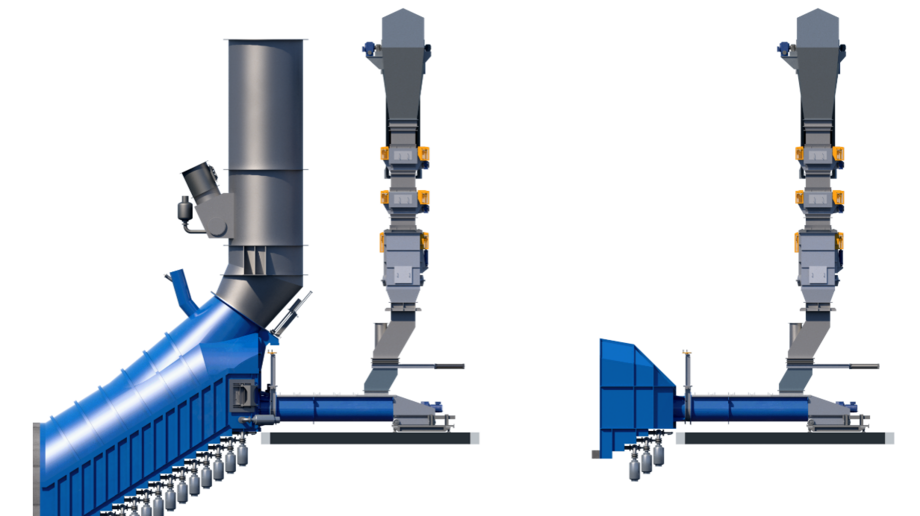

prepol® SC - Step Combustion Chamber

The prepol® SC step combustion chamber is an add-on for the prepol precalciner® preheater. On this simple combustion grate, waste can burn for more than 1,000 seconds at high temperatures. Compared to conventional calciner technology with only up to 7 seconds of dwell time, the prepol® SC thus opens up a new dimension of combustion: It offers high flexibility for a wide range of wastes, which leads to new fuel cost savings - and paves the way for more sustainable cement production.

Spare parts management

In the spare and wear parts business, we focus on shortening the unscheduled downtimes of our customers‘ plants and improving plant performance.

To achieve this, our team of experts examines the individual production processes and based on their OEM expertise and new material technologies, develops suitable wear part solutions for the respective application in combination with appropriate business models.

Thanks to our long-term experience as an OEM supplier, we can provide innovative spare parts concepts to meet your quality and performance requirements: on the one hand, the engineering and manufacturing of individual spare parts in line with your requirements; on the other hand, the ongoing development and enhancement of spare parts and components to increase the availability and performance of your plant. We also offer spare and wear parts for plants that were engineered and erected by third parties.

Modernisation measures

The prepol® SC was developed with innovative features to meet customer requirements. Because the combustion chamber is connected to the tertiary air duct, the hot air can deliver what is needed for complete and successful combustion: Heat for drying and ignition and oxygen for safe and complete combustion.

The design is modular, resulting in easy integration into almost any existing plant. In addition, easy maintenance and high availability of the furnace operation is ensured as there are no moving parts in the combustion chamber.

The stepped grate can be connected to any type of precalciner loop and is nothing more than a tube-like extension: small in dimensions but with huge combustion potential! The grate area of the unit is large enough to offer the waste a residence time of more than 1,000 seconds.

On-site services

Maximum availability of the system is crucial for economic success. To ensure this, we offer you various forms of inspection, repair and maintenance services by our trained specialists. Our offer includes numerous measures that can be carried out individually or combined according to your requirements.

Highlight Services

- Inspections

- Repair services

- Training

Digital services

Highlight Services

- Experience since 2012

- Various communication options

- Worldwide availability of high-end

References

Danucem, a member of the CRH Group, has commissioned us with the engineering and delivery of a prepol® SC combustion chamber for the Turna plant in Slovakia. The customer will thus reduce its fuel costs and CO2 emissions, as our prepol® SC enables the combustion of waste fuels with a high organic content and the combustion of biomasses.

CRH already operates competing products at other sites and has deliberately chosen our prepol® SC technology. Dr. Uwe Maas, Head of Product Group Fuel Substitution: "The new order confirms that with our prepol® SC we have developed the right technology for the current requirements of our customers. While the order is a premiere for the major CRH group, we have already won a total of 17 orders for a prepol® SC."

In addition to the prepol® SC, the order includes a new tertiary air line, a new furnace head, a furnace outlet seal and a modified chlorine bypass.