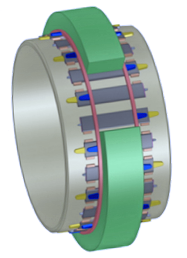

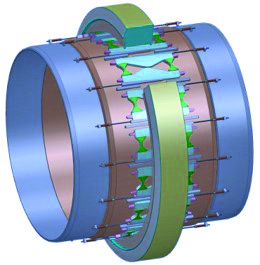

Kiln bearing

With the help of the kiln tyre, the weight forces generated by the rotary kiln are transferred to the foundation via the bearing. In the case of rotary kilns exposed to high temperatures, the kiln tyre is connected to the rotary kiln cylinder by means of a loose or splined tyre fastening.

The vertical and horizontal forces caused by the support load must be absorbed by the foundations via the rollers. Two supporting roller units with two supporting roller bearings and the associated base plates are required for each supporting roller station to support the rotary kiln. The supporting roller unit consists of the supporting roller, which is non-detachably connected to the supporting roller axle.

Spare parts management

In the spare and wear parts business, we focus on shortening the unscheduled downtimes of our customers‘ plants and improving plant performance.

To achieve this, our team of experts examines the individual production processes and based on their OEM expertise and new material technologies, develops suitable wear part solutions for the respective application in combination with appropriate business models.

Thanks to our long-term experience as an OEM supplier, we can provide innovative spare parts concepts to meet your quality and performance requirements: on the one hand, the engineering and manufacturing of individual spare parts in line with your requirements; on the other hand, the ongoing development and enhancement of spare parts and components to increase the availability and performance of your plant. We also offer spare and wear parts for plants that were engineered and erected by third parties.

Highlight Services

- Mobile oil circulation lubrication

- Standard initial parts: Races, track rollers, track roller bearings, bearing housings, track ring mounting systems, short delivery times for bearing shells as these are stocked by polysius®.

Modernisation measures

Highlight Services

- Short-term replacement of entire assemblies according to the latest design criteria

On-site services

Highlight Services

- polgrind®

- polscan®

- poldrive

Digital services

References

- Experience since 2012

- Various communication options

- Worldwide availability