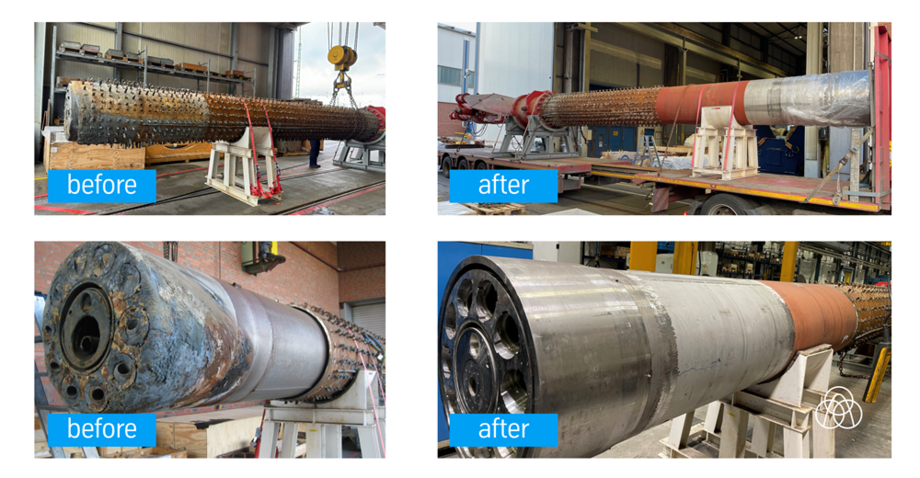

polflame® – High-Quality Repairs at our Neubeckum Facility

The polflame® clinkering zone burner from thyssenkrupp Polysius is a well-established component of the global cement industry. Since its introduction in 1997, this “long-running burner” has been used in more than 200 cement plants worldwide. It reduces fossil fuel consumption while enabling the use of alternative fuels, and at the same time contributes to increased efficiency and improved clinker production quality. However, after years of operation, heat or wear damage may occur.

Insights, Exchange, Development – Our International Technology Forum 2025

Our International Technology Forum has successfully concluded and once again offered valuable insights into key topics in mechanical maintenance. During the two-day event, participants gained in-depth knowledge on the maintenance of rotary kilns, coolers, mills, and crushers. The content was complemented by practical case studies on repairs as well as comprehensive condition assessments, which further enriched the professional exchange.

Our additional service offerings, from field service expertise to advanced remote monitoring, also received great interest.

The program took place both in Münster and at our Communication Center in Beckum, and was rounded off by an exclusive tour of our manufacturing facilities, giving participants a firsthand look behind the scenes.

A highlight of the event was the international participation: 21 attendees from 10 different countries contributed significantly to the success of the forum through their questions, discussions, and open exchange.

We sincerely thank all participants for their engagement and are already looking forward to upcoming events.

The Górażdże modernization project - a remarkable project in many respects

Polish cement manufacturer Heidelberg Materials Poland relied on the technical expertise and technology of thyssenkrupp Polysius to solve problems with its rotary kilns at its Górażdże plant. This modernization order was the largest single order to date for the thyssenkrupp Polysius Service Team in terms of value - and this one was for kiln lines from a third-party supplier.

Technology Forum 2025

From May 12–16, 2025, we welcomed around 30 participants to our Technology Forum in Germany, focused on service and maintenance of mills, crushers, and rotary kilns — the core components of efficient production. The program offered a dynamic mix of deep technical sessions, networking opportunities, and hands-on insights. A highlight for many was the tour through our production facility — an up-close look at the technology and innovation behind our solutions.

The mix of theory, practice, and direct exchange with our experts was especially appreciated.

If you’re already interested in the next national event – we’ll be back in 2026!

thyssenkrupp Polysius and SaltX Initiate Collaboration to Develop Emission-Free Production Facilities

thyssenkrupp Polysius and SaltX have signed a Letter of Intent (LOI) to jointly develop the next generation of fully electrified production facilities.

Read the full article here!

thyssenkrupp Polysius wins engineering contract for the world’s largest activated clay plant in Brazil, to be largely powered by renewable electricity

Circlua, headquartered in Belo Horizonte (MG, Brazil) has entrusted thyssenkrupp Polysius to perform a Front-End Engineering Design (FEED) contract for the construction of the world’s largest activated clay plant with a capacity of 3000tpd.

Read the full article here!

thyssenkrupp cooperates with Heidelberg Materials for the GeZero carbon capture project

Heidelberg Materials and thyssenkrupp Polysius have signed a front-end engineering design contract for the plant design of the clinker production line of the GeZero CCS project. The GeZero project in Geseke will be one of the first European cement plants capable of producing Net-Zero cement and clinker on a CCS (Carbon Capture and Storage) basis. The planning includes a potential capture capacity of around 2,000 tons per day, including the polysius® pure oxyfuel process.

Read the full article here!

Eagle Materials Inc. entrusts thyssenkrupp Polysius with the modernization and ex-pansion of its Cement Plant in Laramie, Wyoming

Eagle Materials Inc. has awarded thyssenkrupp Polysius with the modernization and expansion of its Laramie, Wyoming cement plant. The existing plant, which became operational in 1926, provides cement to several markets, including the growing northern Colorado area, Nebraska, Utah, and Wyoming.

Read the full article here!

Enhance your plant’s performance with »The Field Service Team« of thyssenkrupp Polysius!

If a problem occurs, action needs to be taken quickly. No challenge for our Field Service Team: They don’t only detect malfunctioning early, but also eliminate it swiftly on-site. With state-of-the-art tools at hand, they can visually inspect your machine or measure it through cutting-edge scanners.

But we can go beyond that: We offer a comprehensive overview of your plant and provide customized recommendations on preventive maintenance and modernization. Say goodbye to unexpected downtimes and get ready for increased plant availability and optimized components!

Get to know the Field Service portfolio here: TK The Field Service Team | Home (the-field-service-team.com)

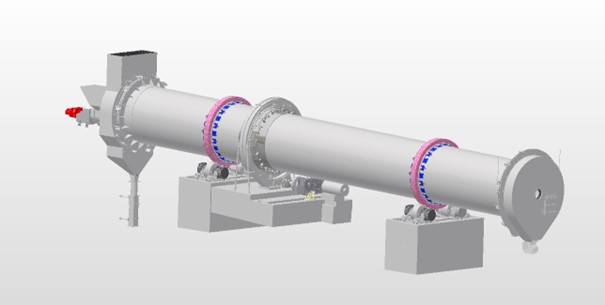

Jansen Recycling BV from Eindhoven orders a kiln

The Dutch company Jansen Recycling BV has commissioned thyssenkrupp Polysius to build a new rotary kiln for its plant in Eindhoven. Jansen processes more than 1.2 million tonnes of inert waste (excavated soil, construction waste, mineral construction waste) annually, 95% of which is recycled or recycled into high-quality certified products.

Read the full article here!