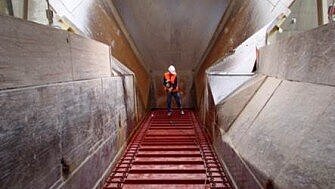

Apron Feeder

If your apron feeder needs to be repaired or replaced, thyssenkrupp Polysius offers its know-how and qualified personnel to carry out the necessary work. Our crusher technology experts can install a modern apron feeder of the latest technology in the existing plant. Based on various aspects regarding technology, installation and costs, it has to be decided whether the old main girder can or should continue to be used.

Spare parts management

In the spare and wear parts business, we focus on shortening the unscheduled downtimes of our customers‘ plants and improving plant performance.

To achieve this, our team of experts examines the individual production processes and based on their OEM expertise and new material technologies, develops suitable wear part solutions for the respective application in combination with appropriate business models.

Thanks to our long-term experience as an OEM supplier, we can provide innovative spare parts concepts to meet your quality and performance requirements: on the one hand, the engineering and manufacturing of individual spare parts in line with your requirements; on the other hand, the ongoing development and enhancement of spare parts and components to increase the availability and performance of your plant. We also offer spare and wear parts for plants that were engineered and erected by third parties.

Highlight Services

- Low maintenance thanks to robust construction

- Various conversion options, e.g.:

- Conversion from slide rail system to lubrication-free sliding system

- Conversion from hydraulic to electric drive

- Conversion from pushcart to apron feeder in less than three weeks

Typical spare parts for apron conveyors:

- The drive shaft consists of shaft, gears, pinions and bearings.

- The end shaft consists of shaft, pinions, bearings and tensioning device (screws or hydraulics).

- Sprocket

- Slide rails

Modernisation measures

Over time, the demands placed on your production plants change. In support we offer you our thyssenkrupp Polysius services in the field of revamps, modernization and renovation. With innovative solutions, modern parts and customized upgrades we help your plants to become up-to-date. Cutting-edge process technology and modern components increase the lifetime of your plant. Thereby, our services effect individual plant components and the plant as a whole.

On-site services

Maximum availability of the system is crucial for economic success. To ensure this, we offer you various forms of inspection, repair and maintenance services by our trained specialists. Our offer includes numerous measures that can be carried out individually or combined according to your requirements.

Otherwise, we can offer a site survey, including a 3D laser scan, to design our machine according to the facility's requirements. This ensures that the machine fits into the plant with a minimum of on-site modifications. Already in more than 300 plants worldwide, thyssenkrupp Polysius' RKF design has proven to be robust and low-maintenance.

Digital services

Thanks to our state-of-the-art remote support tools, we are always close to you - even when you are far away. Our specialists provide you with real-time on-site support, whether it's for troubleshooting or regular maintenance. Using online live video support, we can transmit sounds and images of your work area directly to our experts. This allows us to check your system precisely - from your perspective - and thus support you quickly, effectively and, above all, inexpensively.

References

Re-use and refurbishment of apron feed conveyor and spillage

Plant References

Ashka Cement – refurbished apron & spillage conveyor for energy saving

Project description

Ashaka Cement contracted thyssenkrupp Polysius to modernize a feed conveyor and spillage. Parts of the old apron conveyor and spillage conveyor were removed and replaced with the new machine components. It was possible to retain the existing drives, the main and longitudinal beams.

Results

- Reduction of power consumption by 10 %

- Cost savings through maintenance optimization by 20 %

Modernization on apron feed conveyor allows a successful and efficient project execution

Plant References

Cementos del Norte – modernization of feed conveyor

Project description

Cementos del Norte contracted thyssenkrupp Polysius to modernize a apron feed conveyor. Parts of the old apron feed conveyor were removed and replaced with the new machine components. It was possible to retain the existing drives, the main and longitudinal beams, and the drive and return shafts. The existing drive shaft was re-machined while all other components were delivered as new items.

Results

- Reduction of power consumption by 10 %

- Cost savings through maintenance optimization by 20 %

Customer: Cementos del Norte

Location: Honduras

Plant type: Crushing plant for cement production

Service type: Plant modernization

Schwenk Zement KG – modernization of feed apron conveyor

Plant References

Schwenk Zement KG – modernization of feed apron conveyor

Project description

SCHWENK Zement KG contracted thyssenkrupp Polysius to modernize a feed apron conveyor. As special challenge, the conversion had to be completed in 20 working days during the coldest weeks of the year (- 20 °C and freezing rain). Parts of the old apron conveyor were removed and replaced with the new machine components. It was possible to retain the existing drives, the main and longitudinal beams and the drive and return shafts. The existing drive shaft was re-machined while all other components were delivered as new items.

Results

- Reduction of power consumption by 10 %

- Cost savings through maintenance optimization by 20 %

Customer: SCHWENK Zement KG

Location: Karlstadt, Germany

Plant type: Crushing plant for cement production

Service type: Plant modernization