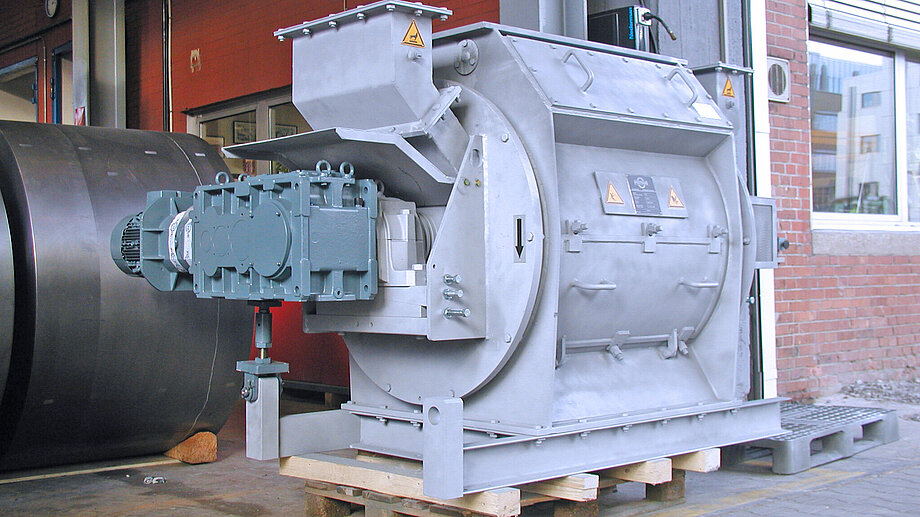

Coarse Feed Valve

Coarse feed valves serve as airlocks and as continuous feeding units for coarse-grained materials. They minimize the effect of false air in a grinding system operated under negative pressure and permit continuous further conveyance of the materials. The conveyed material is supplied to the feed valves at a controlled rate by, for instance, belt conveyors, bucket elevators, continuous conveyors, deep bucket conveyors etc.

This type of feed valve is primarily used upstream of roller mills and ball mills for supplying coarse-grained bulk materials such as limestone and coal with a particle size range of 0–200 mm, depending on the size of feed valve involved. The feed valves are provided with heatable channels to prevent caking during the conveyance of moist or very sticky materials.

Polysius spring-plate cell airlocks are particularly worthy of mention. They are of a robust cast design and have been in use successfully for decades, for air sealing and dosing tasks. The application temperatures are between -40 °C and +450 °C, so they are also very well suited to use in material feeds in preheating systems. The throughput rates range from a few cubic meters per hour to 1,000 m³/h. In addition to the spare parts service for existing airlocks, substitutes for other existing airlocks can also be offered with the spring-plate airlock design.

Spare parts management

In the spare and wear parts business, we focus on shortening the unscheduled downtimes of our customers‘ plants and improving plant performance.

To achieve this, our team of experts examines the individual production processes and based on their OEM expertise and new material technologies, develops suitable wear part solutions for the respective application in combination with appropriate business models.

Thanks to our long-term experience as an OEM supplier, we can provide innovative spare parts concepts to meet your quality and performance requirements: on the one hand, the engineering and manufacturing of individual spare parts in line with your requirements; on the other hand, the ongoing development and enhancement of spare parts and components to increase the availability and performance of your plant. We also offer spare and wear parts for plants that were engineered and erected by third parties.

Modernisation measures

Over time, the demands placed on your production plants change. In support we offer you our thyssenkrupp Polysius services in the field of revamps, modernization and renovation. With innovative solutions, modern parts and customized upgrades we help your plants to become up-to-date. Cutting-edge process technology and modern components increase the lifetime of your plant. Thereby, our services effect individual plant components and the plant as a whole.