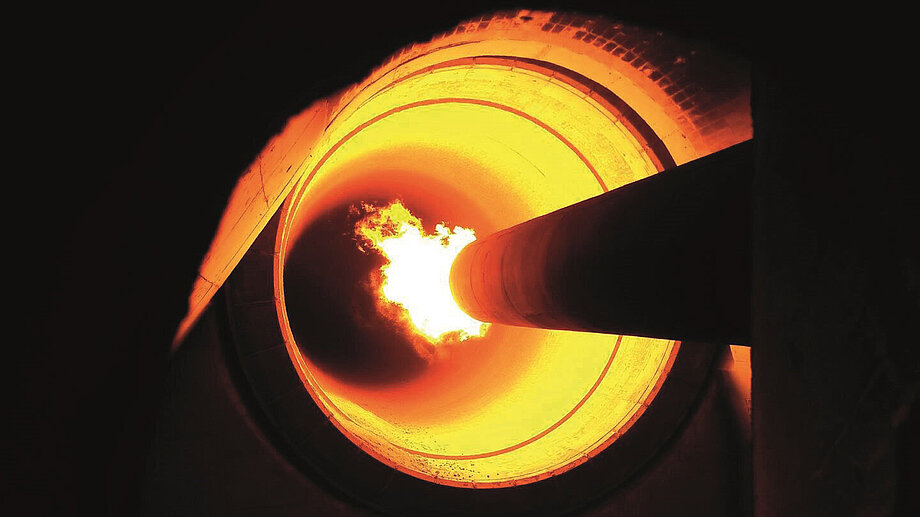

polflame® - Clinkering Zone Burner

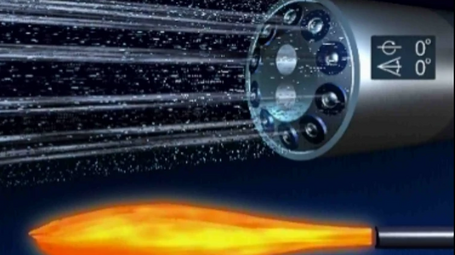

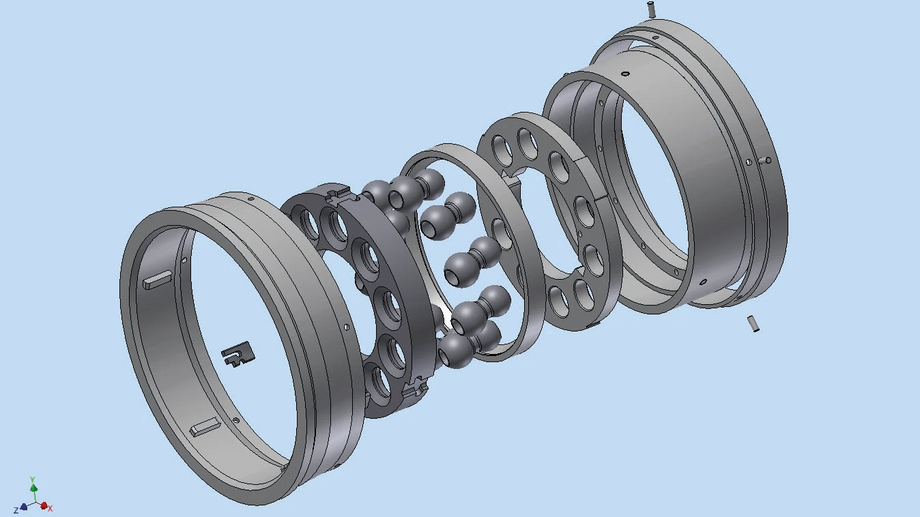

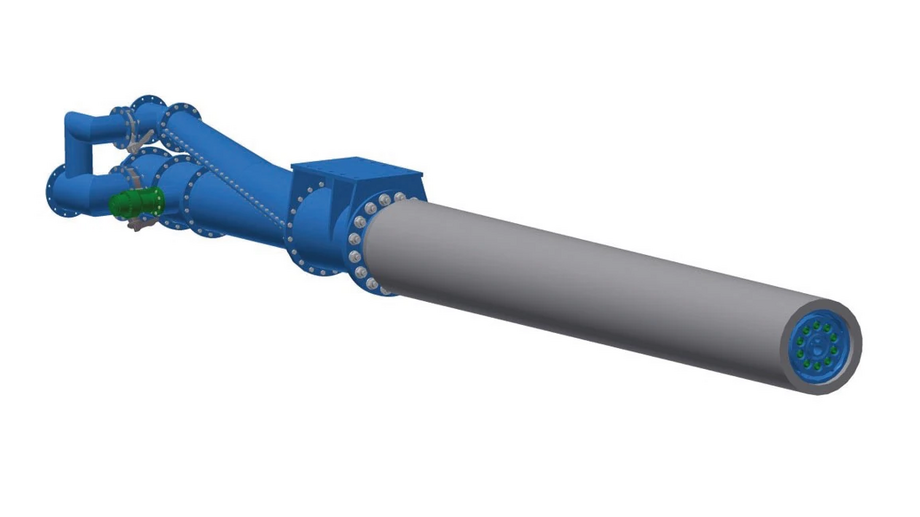

The new polflame® VN burner has been decisively improved in numerous design features. It sets new standards in process firing for rotary kilns. The Polflame® VN can be optimally adjusted to the fuel, product quality and emission requirements. When using substitute fuels, high substitution rates can be achieved, thus saving expensive fossil fuels.

Spare parts management

In the spare and wear parts business, we focus on shortening the unscheduled downtimes of our customers‘ plants and improving plant performance.

To achieve this, our team of experts examines the individual production processes and based on their OEM expertise and new material technologies, develops suitable wear part solutions for the respective application in combination with appropriate business models.

Thanks to our long-term experience as an OEM supplier, we can provide innovative spare parts concepts to meet your quality and performance requirements: on the one hand, the engineering and manufacturing of individual spare parts in line with your requirements; on the other hand, the ongoing development and enhancement of spare parts and components to increase the availability and performance of your plant. We also offer spare and wear parts for plants that were engineered and erected by third parties.

Highlight Services

- Burner lances

- Cooling hoses

- Nozzles

- Connections

Modernisation measures

Over time, the demands placed on your production plants change. In support we offer you our thyssenkrupp Polysius services in the field of revamps, modernization and renovation. With innovative solutions, modern parts and customized upgrades we help your plants to become up-to-date. Cutting-edge process technology and modern components increase the lifetime of your plant. Thereby, our services effect individual plant components and the plant as a whole.

On-site services

Digital services

Highlight Services

- Experience since 2012

- Various communication options

- Worldwide availability

References

Re-use and refurbishment of existing components allow a successful and efficient project execution

Plant References: Vissai Cement Company – Delivery & installation of new kiln burner polflame® VN

Project description

Vissai Cement contracted thyssenkrupp Polysius to deliver our new custom made polflame® kiln burner. A special challenge was the implementation into the existing structure.

Customer: Vissai Cement Company

Location: Ninh Binh, Vietnam

Plant type: Plant for cement production

Service type: Plant modernization