Grinding Technologies

Grinding for a wealth of applications. Cost-effective, reliable and energy-saving: for its high performance range of mills for the grinding of a wide variety of materials, thyssenkrupp Polysius offers solutions to suit your every need.

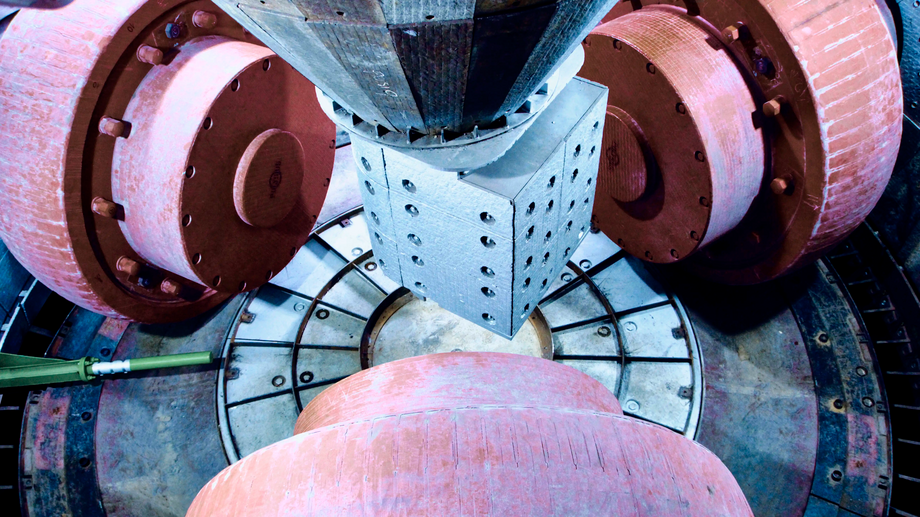

polycom® - High-Pressure Grinding Rolls

Polysius was one of the first to supply high-pressure grinding rolls, and is one of the world‘s leading suppliers. Two of our wear concepts, the compound-cast roll body and the forged roll body with studs, achieve maximum performance in a wide range of raw material, cement and slag grinding applications.

quadropol® - Vertical Roller Mill

In recent years, Polysius has successfully continued step by step the development process for the quadropol® vertical roller mill concept. This compact and modular concept includes the latest market requirements regarding compact plant layout, efficient operation and reliable machine design. Moreover, it also reduces unscheduled downtime. Tailor-made solutions with interchangeable parts are available as well. We also offer spare and wear parts for our customers' quadropol® systems.

Tube mill

Our customers benefit not only from the decades of experience we have gained through successfully commissioning more than 2,200 tube mills, but also from our comprehensive scope of services, ranging from maintenance and OEM spares procurement, to the optimization of existing plants.

sepol® - Separator

The higher the demands placed on the quality of the ground material and the lower the desired energy requirement of the overall grinding system, the more important the efficiency of the separator is. High availability, high selectivity, low specific energy consumption, simultaneous product separation, cooling and drying, as well asshort amortization periods combined with relatively low capital expenditure are the defining features of the sepol® high-efficiency separator.