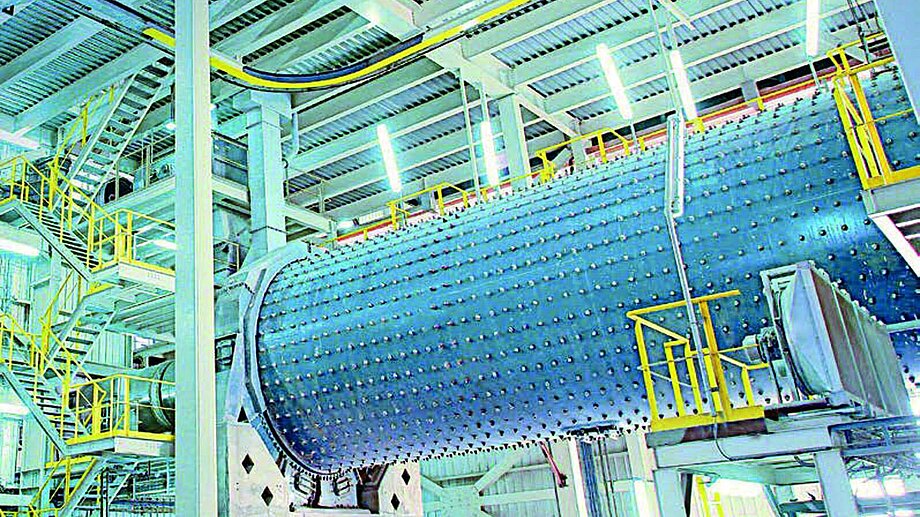

Tube Mill

The classically proven option for cement grinding: Whether as a two-chamber classifier mill in a stand-alone grinding system or as a single-chamber classifier mill in combination with a high-pressure roller mill, the ball mill is a robust and reliable alternative for cement and granulated blast furnace slag grinding.

Spare parts management

In the spare and wear parts business, we focus on shortening the unscheduled downtimes of our customers‘ plants and improving plant performance.

To achieve this, our team of experts examines the individual production processes and based on their OEM expertise and new material technologies, develops suitable wear part solutions for the respective application in combination with appropriate business models.

Thanks to our long-term experience as an OEM supplier, we can provide innovative spare parts concepts to meet your quality and performance requirements: on the one hand, the engineering and manufacturing of individual spare parts in line with your requirements; on the other hand, the ongoing development and enhancement of spare parts and components to increase the availability and performance of your plant. We also offer spare and wear parts for plants that were engineered and erected by third parties.

Highlight Services

Extremely unbreakable and wear-resistant

polalloy is an extremely wear-resistant material from which we manufacture slotted and back panels. These offer considerable advantages over products made of cast materials and rolled steel: This is because polalloy offers not only a high degree of hardness but also excellent toughness - which increases resistance to fracture.

Modernisation measures

Tuning for your ball mill

polalloy is an extremely wear-resistant material used for manufacturing slotted plates and backwall plates. Plates made of this material have significant advantages compared to products made of cast metals and rolled steel because, polalloy offers a high level of hardness and excellent toughness - this minimises the risk of breakage. The further improved diapol 2.0 lifting diaphragm, with types intermediate diaphragm, discharge diaphragm, central discharge diaphragm for double rotators and predrying compartment diaphragm, is the universal solution for your grinding. The air stream and the mill feed material are now separated from each other more effectively. The mill feed material falls directly behind the diaphragm, preventing onward pneumatic conveyance, meaning that the entire effective grinding length is used for grinding.

On-site services

Maximum availability of the system is crucial for economic success. To ensure this, we offer you various forms of inspection, repair and maintenance services by our trained specialists. Our offer includes numerous measures that can be carried out individually or combined according to your requirements.

Highlight Services

- Inspections

- Repair services

- Drive inspection

- Training

Digital services

Thanks to our state-of-the-art remote support tools, we are always close to you - even when you are far away. Our specialists provide you with real-time on-site support, whether it's for troubleshooting or regular maintenance. Using online live video support, we can transmit sounds and images of your work area directly to our experts. This allows us to check your system precisely - from your perspective - and thus support you quickly, effectively and, above all, inexpensively.

References

- Experience since 2012

- Various communication options

- Worldwide availability of high-end