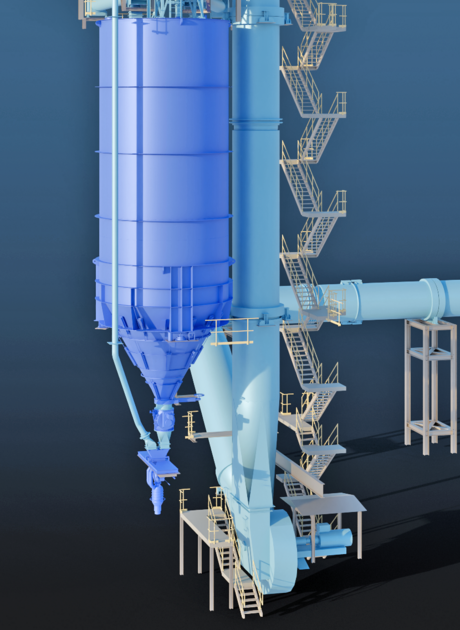

Silo Technology and Pneumatic Conveying

Highlight Services

Polysius offers the following service products for the various silos:

- Spare parts for existing silos

- Replacement of aeration boxes

- Modification of existing silos, such as new material distributors on raw meal silos

- Delivers of new steel-plate silos

- Process-technology advice in the event of outlet problems with, for example, mill feed bins, as well as modification proposals

- Process-technology advice on the operation of raw meal silos, in order to increase the blending effect

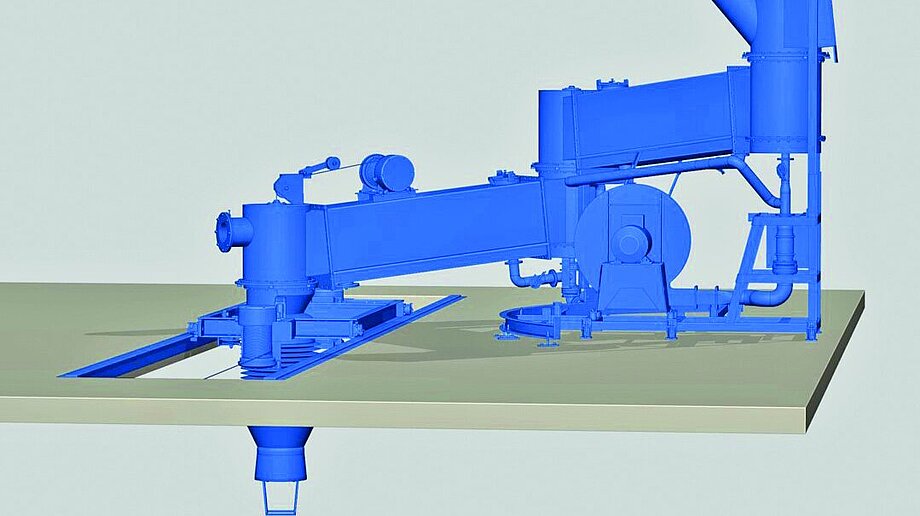

Pneumatic conveying and feeding

At Polysius, pneumatic conveying and dosing has an 80-year-long tradition and has been continuously advanced over this period. For example, the complete modular system for the polysius® pneumatic trough conveyor features all the components and inclinations to meet all process requirements in the cement industry. The portfolio also includes the modern, welded rotary flow-regulating valve with pneumatic actuators.

Highligh Services

In this sector, Polysius can offer the following service products:

- Spare parts for existing equipment

- Replacement of existing equipment with modern machines

- Increased performance of existing systems

- Modifications to existing systems, such as conversion from purely pneumatic raw meal or cement conveyance to a conveying system consisting of pneumatic trough conveyor and bucket elevator

For decades now, Polysius has offered various products for pneumatic tubular conveyance using the lean-phase/dense-phase procedure, such as the polysius® vertical conveyors, the polysius® pressure-vessel conveyors and the polysius® dosing conveyors. For pneumatic tubular conveyance, Polysius offers the following service products:

- Spare parts for existing equipment

- Optimization of existing systems

- Replacement of screw pumps with rotary airlock feeders, in order to reduce operating expenses

At the end of the process chain in a cement plant, cement and binding agents are loaded into tankers. Polysius has completely revised the mobile trough loader that can be used for all loading tasks, such that it is also suitable as a replacement for existing systems. Now, only pneumatic trough conveyors are used to ensure moveability of the bulkloading head in relation to the stationary connection to the system. Further transmission into the pivot points is implemented by means of three conveying joints. This means that practically any longitudinal and transverse travel of the bulk loading head is possible. A frequent application is movement in a longitudinal direction by 6.0 m and movement in a transverse direction by 0.5 m. Here, the bulk loading head can usually be lowered vertically by 2.0 m. For the first time, the trough loader offers complete mechanical and electrical pre-assembly in the workshop. Thanks to the use of the trough sections for the conveying route, the loading device can be supplied in just three completely pre-assembled and cabled loose parts. This means that replacement of a bulk loading spout is also possible later – even during a shift – in order to service it in the workshop, for example. This ensures a high level of availability of the loading point.